Standard composition

1

2

3

4

1

2

3

4

The purpose of this specification is to specify the technical characteristics of the material used in the lacquer-painted door produced within the business and to commit to manufacturing under these conditions.

Door components:

-

In the door construction, the inner frame is made of solid wood:

- It is made from coniferous trees specially dried to an ideal moisture level of 12%.

- After being cleared of knots, the wood is joined using a finger joint system, preventing warping and increasing durability.

- The frame section dimensions are 30*42 mm.

- Air circulation channels of 6*3 mm are opened inside the frames to allow airflow.

- Double-sided reinforcement frames are placed in areas where the lock case will be opened.

- The internal structure is filled with kraft paper (honeycomb filling) with a resin-based TSEK certificate and a strength of 1.1 kg/cm² as standard. (Upon request, chipboard can be used as an optional inner filling material.)

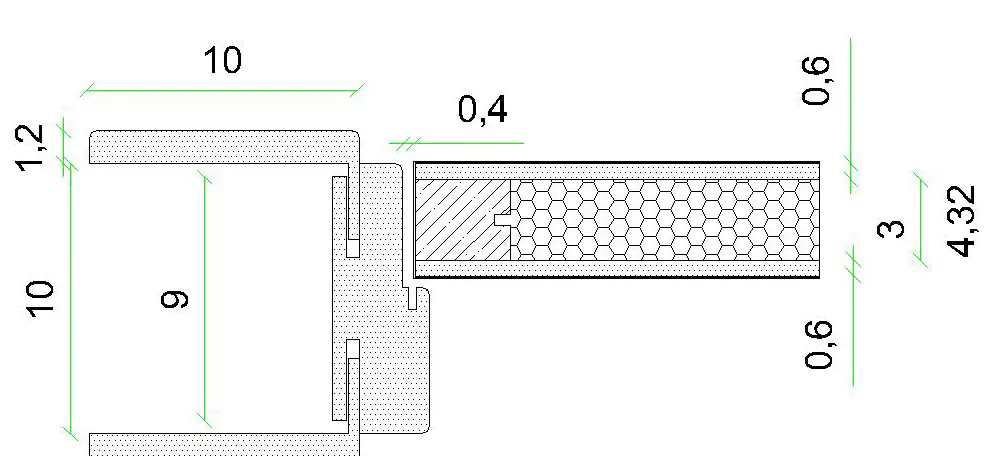

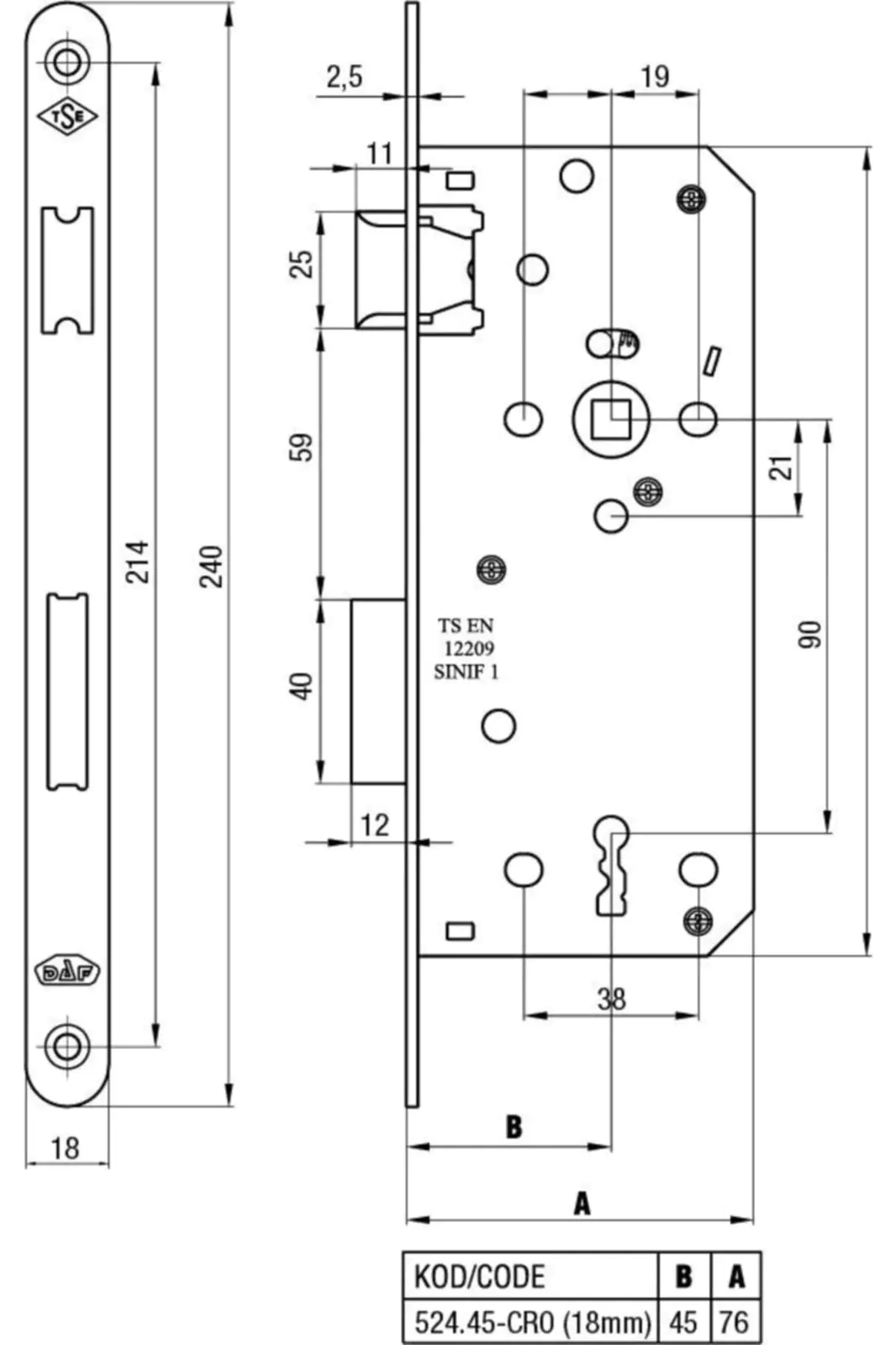

- 6 mm thick MDF boards are pressed on both sides of the door panel. Glue that is safe for human health is used. The lock area is prepared for a 45 mm oval lock. Hinge slots and lock counterparts are cut upon special request.

- For doors with glass panels, solid wood frames are placed during the frame construction at the locations where glass openings will be made.

- Matte lacquer paint will be applied to the door surface.

- Paintable (ABS) edge bands are applied to the door edges using polyurethane glue that is resistant to high temperatures.

- The door panel is produced with a pomel (without rabbet) design.

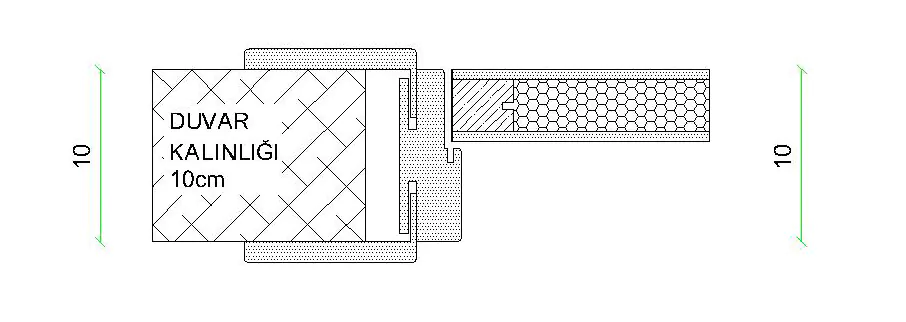

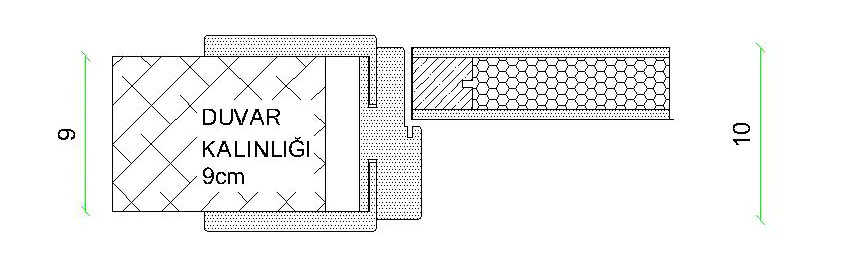

- The frame thickness will be a construction frame with a total of 36 mm (18 mm MDF + 18 mm MDF).

- The frames will be produced with channels for adjustable molding installation, a seal groove channel, and a rabbet cutout.

- Polypropylene (PP) foil will be wrapped around the surfaces of the frames using polyurethane glue.

- The frame headers will be joined at a 45-degree angle. A hole is made for the frame assembly screw.

- A seal groove is opened inside the rabbet of the frame for sound and heat insulation purposes.

- The side moldings (L detail) are 12 mm thick and 8 cm wide. The top moldings are 08 mm thick and 80 mm wide.

- The surfaces of the moldings will be wrapped with polypropylene (PP) foil using polyurethane adhesive.

- They will be produced from MDF, suitable for the adjustable molding detail.

Our doors are painted with polyurethane paint on our state-of-the-art automated paint line.

For some technical features further options are available.

The Solutions For The Project

Tubular Door Leaf

Semi Solid Wood

Honey Comp