Standard composition

1

2

3

1

2

3

The purpose of this specification is to specify the technical characteristics of the materials used in the wooden veneer doors produced within the company and to commit to manufacturing under the specified conditions.

Door components:

-

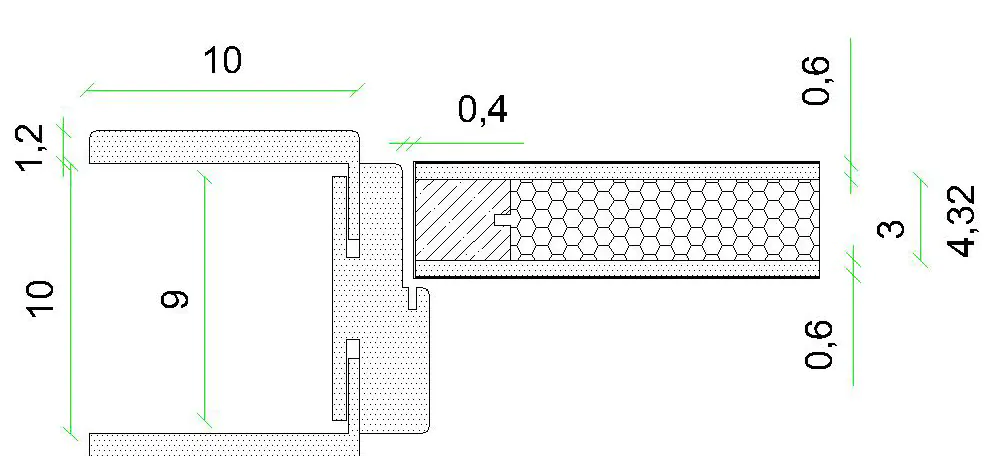

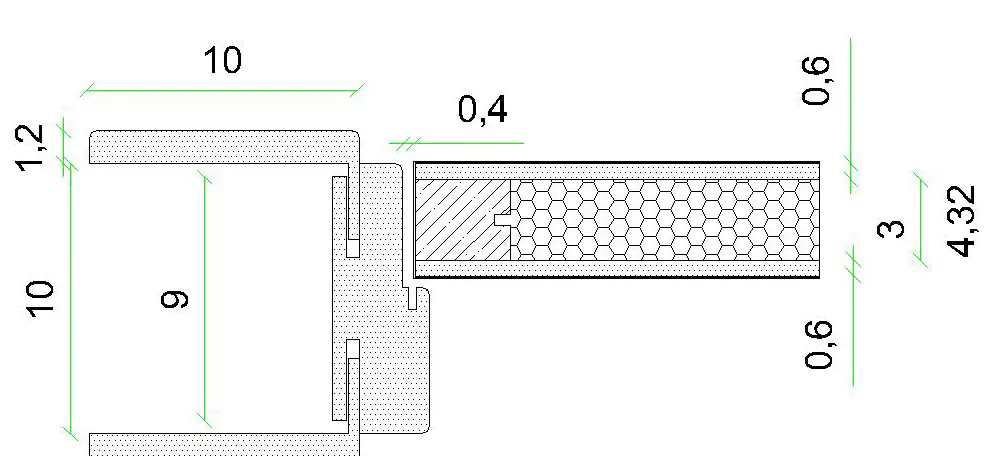

In the door construction, the internal frame solid material:

- Is made from specially dried coniferous trees with an ideal moisture level of 12%.

- After removing the knots, it is joined using the finger-joint system, eliminating the risk of material warping and increasing durability.

- The frame section is 30*42 mm.

- Air circulation channels with dimensions of 6*3 mm are opened inside the frames.

- Double-sided lock reinforcement frames will be placed where the lock hole is to be opened.

- Kraft paper (honeycomb filling) with a resin-based TSEK certificate and 1.1 kg/cm2 resistance is used inside the frame material.

- A 6 mm MDF panel veneered with 0.60 mm wood veneer is pressed on both sides of the door leaf. Glue compliant with health standards (harmless to human health) is used in these processes.

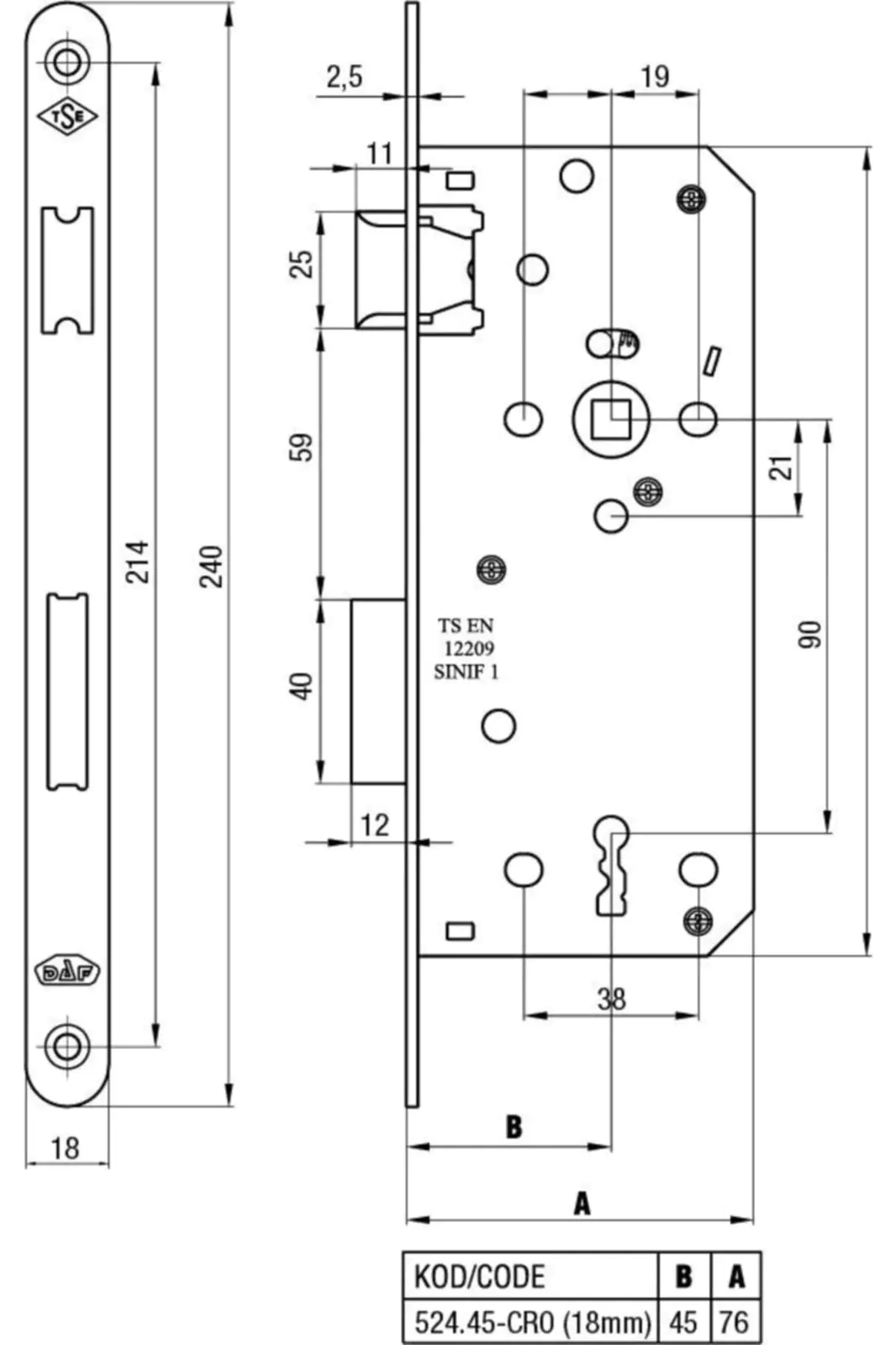

- The lock hole is opened for a 45 mm oval lock. Hinge slots and lock counterparts can be opened upon special request.

- In addition, in doors with glass panels, solid frames are placed where the glass openings are located during the frame formation phase.

- A 1 mm thick wood edge band is used on the edges of the door panels.

- The door leaf is produced in a pomel (without a rabbet) design.

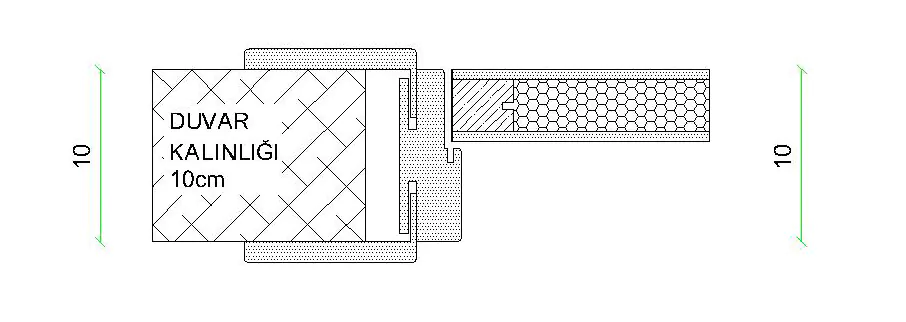

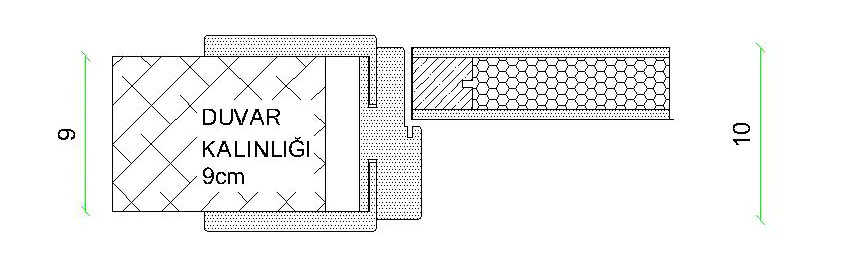

- The thickness of the frame will be 36 mm in total, consisting of (18 mm MDF + 18 mm MDF) as a construction frame.

- The frames will be produced with veneer installation channels suitable for adjustable casings, a gasket channel, and a rabbet.

- The surfaces of the frames will be wrapped with 0.60 mm wood veneer using polyurethane glue.

- The joints of the frame headers will be at a 45-degree angle. A slot will be opened for the frame assembly screw.

- A gasket channel will be opened inside the frame rabbet for sound and heat insulation.

- Side casings in the "L" detail are 12 mm thick and 8 cm wide. The upper casings are 08 mm thick and 80 mm wide.

- The surfaces of the casings will be wrapped with wood veneer using polyurethane glue.

- They will be produced from MDF, suitable for adjustable casing detail.

For some technical features further options are available.

The Solutions For The Project

Tubular Door Leaf

Semi Solid Wood

Honey Comp